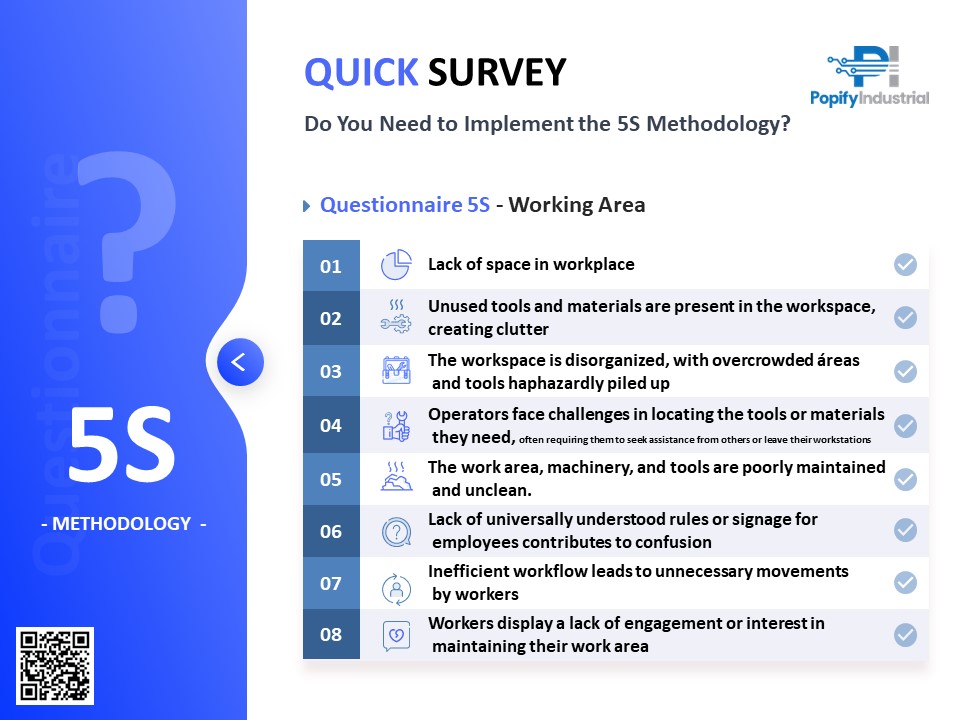

Necesitas aplicar la famosa metodología 5S?

Sep 01,2023

The 5S methodology is a systematic approach for workplace organization and visual management. It originated in Japan and is widely used in various industries to improve efficiency, safety, and overall productivity. Each "S" represents a specific step in the methodology:

1. Sort (Seiri): This step involves separating necessary items from unnecessary ones and removing any clutter or unused items from the workspace. It helps in creating a clean and organized work environment.

2. Set in Order (Seiton): In this step, the necessary items are arranged in an organized manner to ensure easy accessibility and efficient workflow. Tools, equipment, and materials are assigned specific locations, labeled appropriately, and stored in a manner that minimizes waste and promotes visual management.

3. Shine (Seiso): This step focuses on cleaning and maintaining the work area. Regular cleaning practices are implemented to ensure cleanliness, prevent dirt or debris buildup, and identify any maintenance issues or abnormalities.

4. Standardize (Seiketsu): Standardization involves establishing clear and consistent procedures, guidelines, and visual controls for maintaining the first three steps. It includes creating visual instructions, checklists, and schedules to sustain the organized workspace and ensure everyone follows the established standards.

5. Sustain (Shitsuke): The final step emphasizes the importance of continuous improvement and long-term sustainability. It involves fostering a culture of discipline, adherence to standards, and ongoing training and communication to ensure the 5S practices are maintained and improved over time.

The 5S methodology aims to create a clean, organized, and efficient work environment that promotes safety, reduces waste, enhances productivity, and supports continuous improvement efforts.

Noticias relacionadas