Segundo paso de implementar 5S

Oct 11,2023

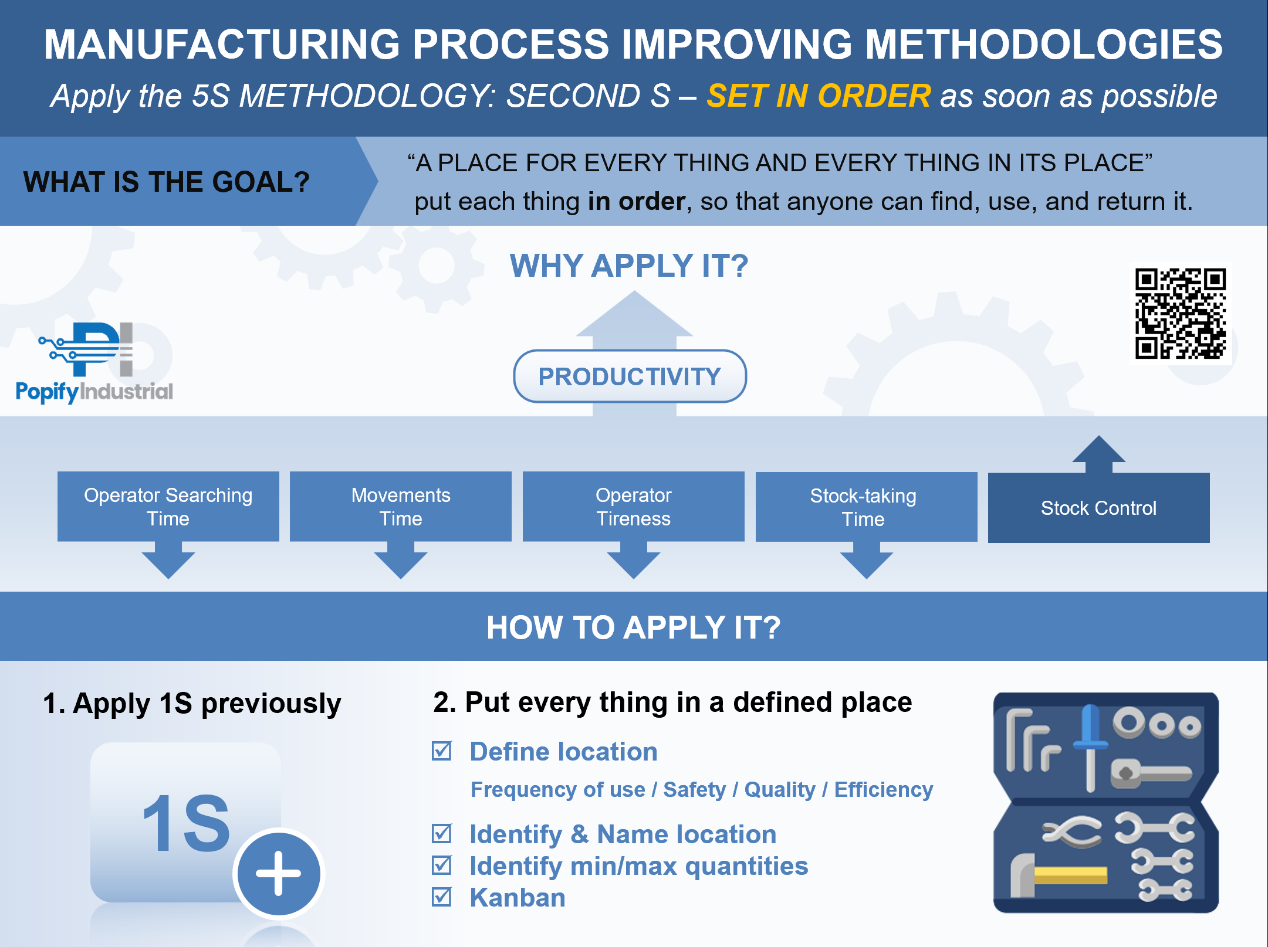

Revolutionizing Workspace Efficiency: Implementing 'Set in Order'

- Phase Two of the 5S Methodology

Objective of Implementing the 'Set in Order' Phase:

To create an organized workplace so that operators can quickly and easily find, use, and return items to their designated places. The key principle of this phase is ”A place for everything and everything in its place.”

Benefits of Implementing the 'Set in Order' Phase:

-

- Quick identification of missing items: By organizing and assigning specific locations for each item, operators can easily recognize if any necessary items are missing.

- Decreased Search Time: A well-organized workspace with designated places for items reduces the time spent searching for things, increasing overall efficiency.

- Decreased Movement Time: When items are properly organized and easily accessible, workers spend less time and effort moving around to retrieve the items they need.

- Lower Physical and Mental Fatigue: An orderly, logical work environment helps in reducing physical and mental fatigue among workers.

- Reduced Production Inventory Time: With items clearly organized and identifiable, conducting production inventory becomes faster and more efficient.

All these factors combined lead to an increase in overall Productivity.in the workplace.

Steps to Implement the 'Set in Order' Phase:

-

- Select an area where you have already applied the first phase of the 5S methodology, as there is no need to organize unnecessary elements.

- Define a specific location for each item based on criteria such as frequency of use, quality, efficiency, ergonomics, and safety. To determine the most suitable location, To ascertain the most appropriate location, consider conducting a Method analysis of the tasks performed in the workplace and a detailed study of the Layout.

- Identify the locations of the items using labels with names or references, painted silhouettes matching the shape of the elements, symbols or colors, or painted lines or adhesive tapes on the floor or walls.

- Define the physical aspects of the organization, including the maximum quantity of each item allowed in a specific location (as defined in the first phase of 5S) and the minimum quantity that should be present to alert operators to restock (implementing elements of the Kanban methodology). To perform this step accurately, it is important to have knowledge of the Cycle time of tasks, which can be determined through a prior Time study.

Noticias relacionadas