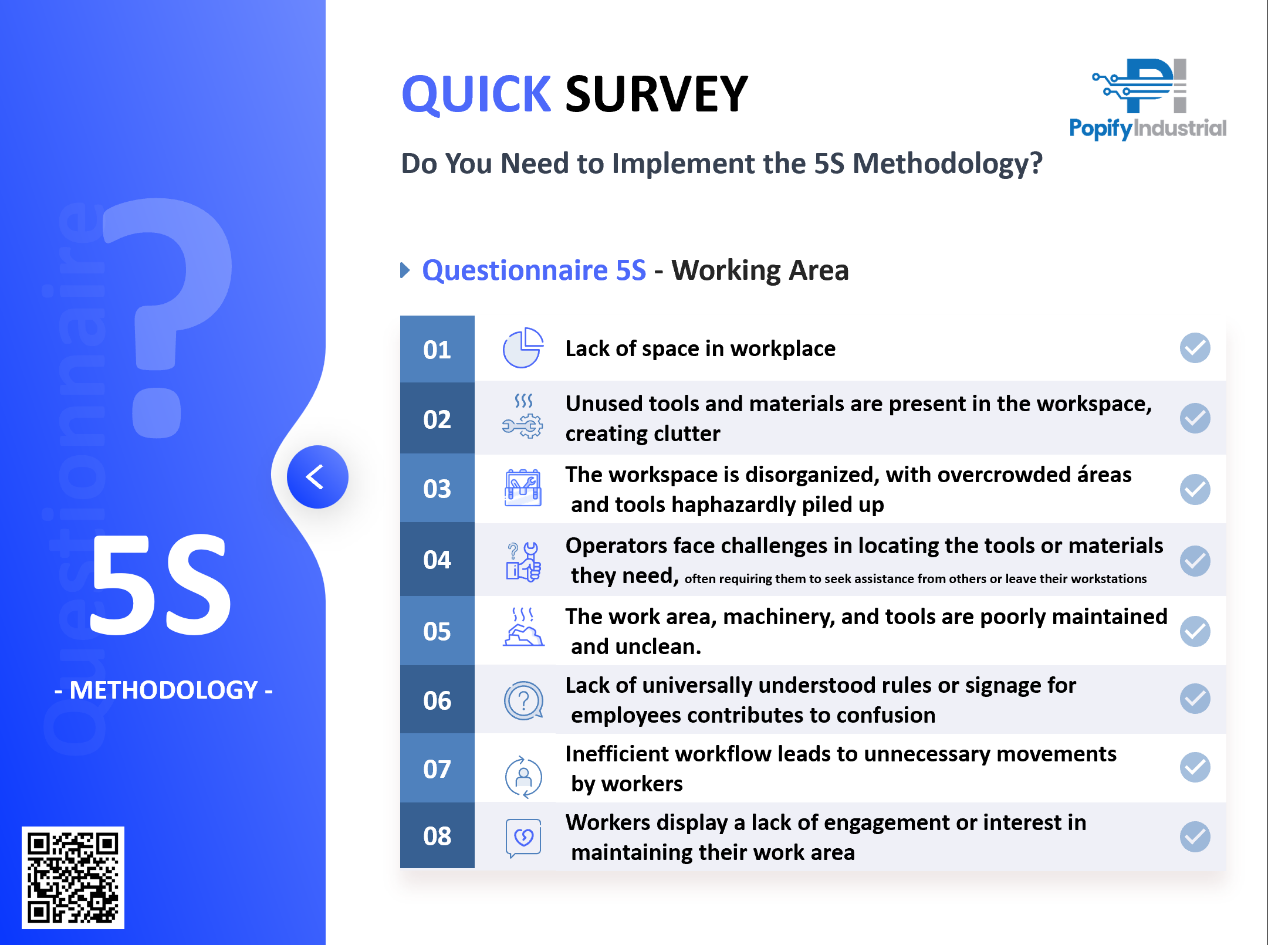

Tercer paso de implementar 5S

Nov 16,2023

The Power of Cleanliness: Boosting Productivity through “Shine”

- the 3rd phase of 5S methodology.

Objective

To ensure that the workplace is in optimal conditions by performing necessary cleaning actions, creating a perfectly clean environment that allows for quick detection of any anomalies.

Benefits of Implementing the Shine Phase:

- Reduction in machine and equipment failures: Regular cleaning minimizes the accumulation of contaminants that can degrade machine performance. By ensuring tools and equipment are free from dust and debris, and by verifying the proper lubrication, the frequency of equipment breakdowns is diminished.

- Enhanced Corporate Image: A clean and well-maintained workplace reflects positively on the company’s dedication to excellence, impressing both employees and visitors alike.

- Prevention of possible damages to materials and products: Regular cleaning helps to prevent dirt, debris, or contaminants from affecting the quality and integrity of materials and products.

- Swift Problem Detection: A well-maintained area facilitates the quick identification of issues, allowing for immediate corrective action.

- Increased operator satisfaction in the workplace: A clean and organized environment contributes to the satisfaction and well-being of operators, creating a more pleasant and conducive work atmosphere.

- Improved operator knowledge of machinery: Regular cleaning activities involve operators in the maintenance and care of machinery, leading to better familiarity and understanding of the equipment they work with.

- Increased equipment lifespan: Regular cleaning and inspection by responsible personnel contribute to the early detection of potential issues, ensuring timely maintenance and extending the lifespan of equipment.

By achieving a clean and well-maintained workplace, Productivity in the manufacturing process can be increased.

Steps to Implement the Shine Phase:

- Choose an area where the "Set in Order" phase has already successfully established.

- Establish a cleaning procedure that outlines the specific cleaning tasks to be performed. For example, tasks could include cleaning fixtures and tools using alcohol and a chamois, and sweeping and cleaning the area after work using a broom and dustpan.

3. Execute and Monitor: Consistently carry out the outlined cleaning procedures and ensure that the set standards are upheld. Periodic audits can be instrumental in maintaining the rigor of the Shine phase.

Noticias relacionadas